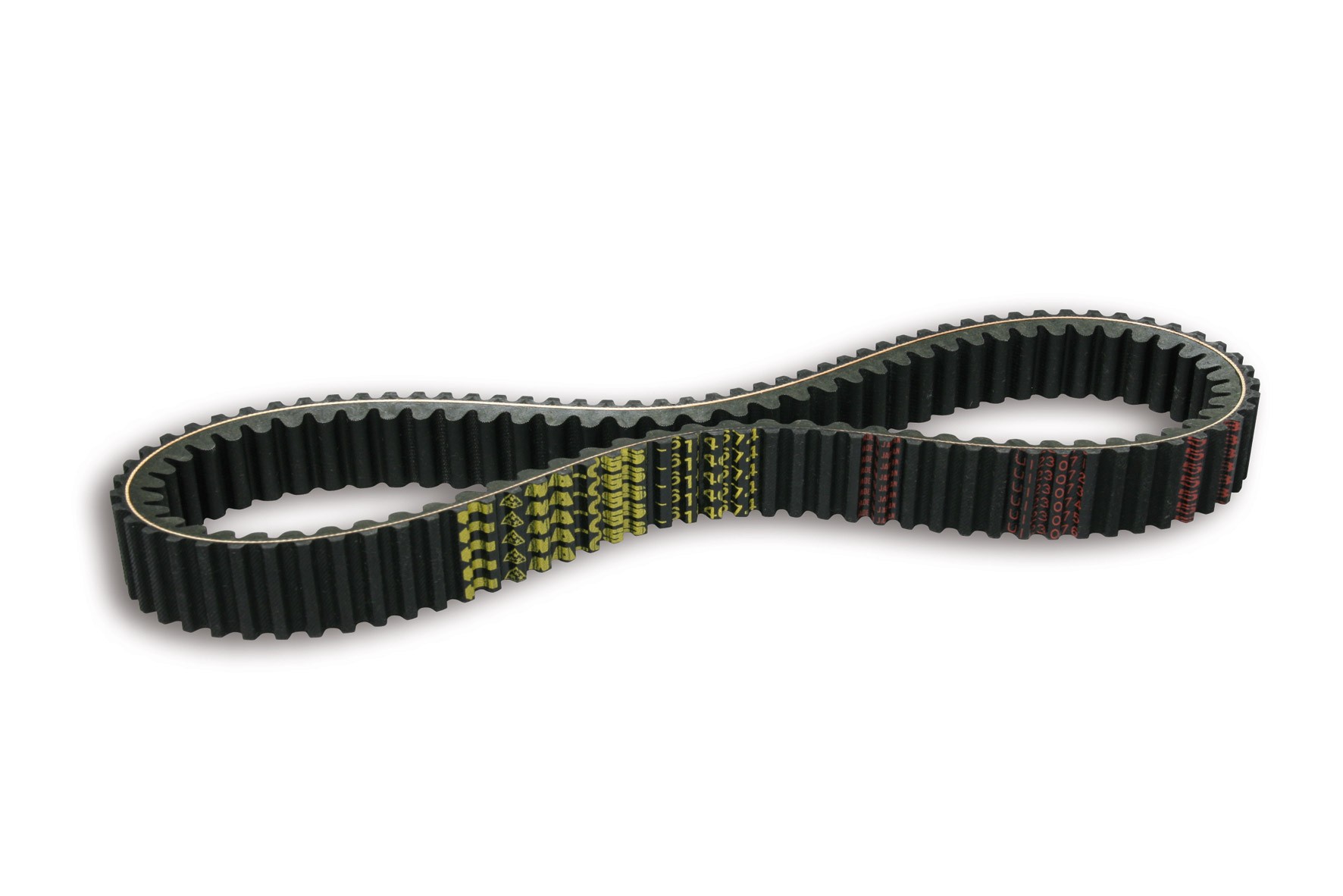

Today, we will look at the many types of belts used in power transmission. Belts are also made in the same manner. It transmits power from one shaft to other using pulleys that revolve at the same or different speeds. Belt and rope materials must be robust and flexible, with a high coefficient of friction to enable maximum efficiency. As a result, the material of the belts is very important in power transmission. The correas de transmisión materials are classed as follows.

- Leather belt, this is the most commonly used belt in workshops. It’s fashioned from 1.2-1.5 meter-long strips cut from each side of the bone of top-quality steer skins. The flesh side of the lather is interlaced and parallel to the surface, while the hair side is smoother and firmer. The leather might be oak- or mineral salt-tanned. The strips are bonded together to improve belt thickness. According to this, the belt is classified by the number of layers, such as single ply, double ply, and so on.

- Canvass or cotton duck are used in fabric belts. These belts are constructed by sewing together three or more layers. These belts are also braided into the required width and thickness of a strip. These belts are treated with filler, such as linseed oil, to make them waterproof and to protect the fibres. Cotton belts are appropriate for use in warm regions, humid environments, and exposed situations. Cotton belts are utilised in farm machines, belt conveyors, and other similar applications because they require less maintenance. Knowing about the correas de transmisiónis also important to know because these are something important when you use these machines.

- Rubber belts are comprised of layers of cloth impregnated with rubber composition and have a thin coating of rubber on the faces. These belts are extremely flexible, but they are quickly ruined when exposed to heat, oil, or grease. Because the rubber is elastic, these belts may be simply created infinite. These belts are proven to be excellent for saw mills and paper mills when they are exposed to dampness.

- Balata belts are identical to rubber belts, except that balata gum is used instead of rubber. These belts are acid and water resistant, and they are unaffected by animal oils or alkalies. This belt is stronger than a rubber belt.

- These are the most common types of transmission belts materials used to make them.